Combined Heat and Power Can Cut Carbon Emissions & Energy Costs for Better Building Efficiency

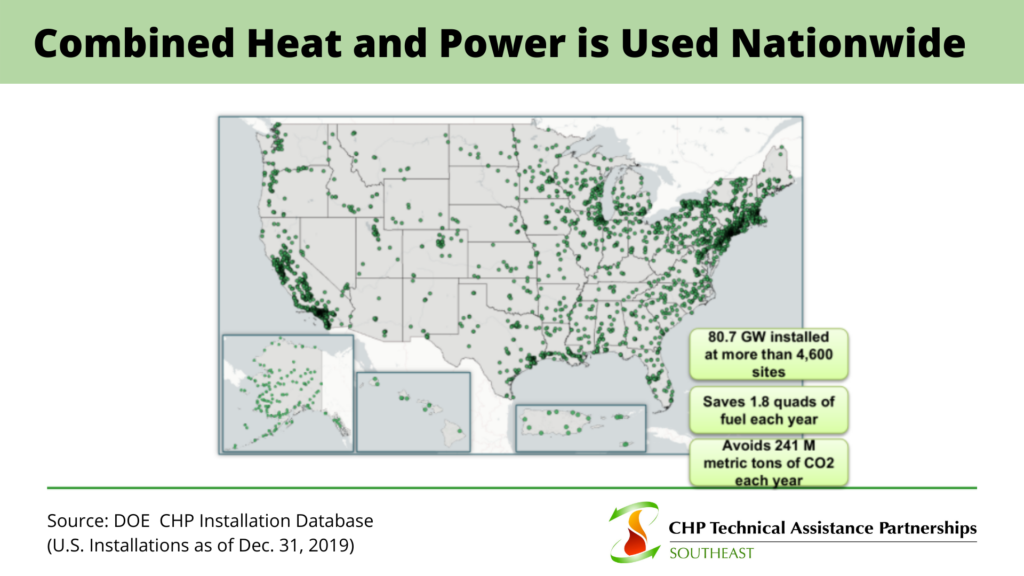

Combined heat and power (CHP) technologies hold the potential to improve the nation’s energy security and resiliency while dramatically reducing emissions of harmful pollutants. Existing applications of combined heat and power in the United States avoid more than 1.8 quadrillion Btus of fuel consumption and 241 million metric tons of carbon dioxide annually compared to the less efficient production of electric and thermal energy separately, according to the U.S. Environmental Protection Agency.

Combined heat and power (CHP) technologies hold the potential to improve the nation’s energy security and resiliency while dramatically reducing emissions of harmful pollutants. Existing applications of combined heat and power in the United States avoid more than 1.8 quadrillion Btus of fuel consumption and 241 million metric tons of carbon dioxide annually compared to the less efficient production of electric and thermal energy separately, according to the U.S. Environmental Protection Agency.

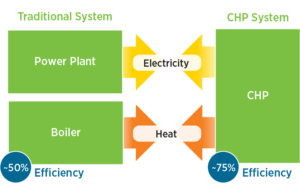

CHP, also known as cogeneration, is an energy efficient technology that generates electricity and captures heat that would otherwise be wasted to provide useful thermal energy for heating or cooling from a single fuel source. Since the electricity is produced onsite, CHP also requires less fuel and avoids transmission and distribution losses that occur when electricity travels over power lines.

CHP, also known as cogeneration, is an energy efficient technology that generates electricity and captures heat that would otherwise be wasted to provide useful thermal energy for heating or cooling from a single fuel source. Since the electricity is produced onsite, CHP also requires less fuel and avoids transmission and distribution losses that occur when electricity travels over power lines.

Nearly two-thirds of the energy used by conventional electricity generation is wasted in the form of heat discharged to the atmosphere and additional energy is wasted during the distribution of electricity to end users. Systems with CHP technologies can achieve up to 85 to 90 percent efficiency by capturing and using heat which would be wasted in the form of heat discharged to the atmosphere, while traditional power systems only achieve 45 to 50 percent efficiency.

As the nation’s demand for power continues to rise, there is also an expanding need for resilient, efficient and low-carbon energy solutions. CHP systems have technological and cost-effective potential to be a viable alternative for power supplies in residential, commercial, municipal, institutional and manufacturing buildings.

CHP is used in over 4,400 facilities nationwide including manufacturers, municipalities, institutions, and residential and commercial buildings. The University of Montana is currently constructing a CHP facility that is expected to reduce the university’s greenhouse gas (GHG) emissions by 23 percent– the largest reduction in the university’s emissions footprint since it launched its climate efforts a decade ago. Once the system is brought online, it’s estimated that the new facility will save the university up to $2 million a year.

CHP has been employed for years, providing highly-efficient electricity and process heat to some of the most vital industries and largest employers, urban centers, and campuses in the United States. The U.S. Department of Energy reports 82 gigawatts of existing CHP capacity in the United States with technical potential for twice as much to meet existing energy demands.

NC State University already has two combined heat and power facilities operating on campus located at the Cates (picture courtesy of NC State’s Sustainability Office) and Centennial Central Utility Plants. With their two CHP systems, NC State has ambitious sustainability goals targeting reduced waste, GHG emissions and energy consumption. With a goal of reaching carbon neutrality by 2050, the 17.5 megawatts (MW) of CHP on NC State’s campus equates to a 12 percent overall reduction of GHG emissions to support the university’s Climate Action Plan.

NC State University already has two combined heat and power facilities operating on campus located at the Cates (picture courtesy of NC State’s Sustainability Office) and Centennial Central Utility Plants. With their two CHP systems, NC State has ambitious sustainability goals targeting reduced waste, GHG emissions and energy consumption. With a goal of reaching carbon neutrality by 2050, the 17.5 megawatts (MW) of CHP on NC State’s campus equates to a 12 percent overall reduction of GHG emissions to support the university’s Climate Action Plan.

Clemson University in South Carolina recently added a 2.8 MW steam turbine generator to the 15 MW CHP system already on their campus. The CHP plant, owned and operated by Duke Energy, provides Clemson with steam while also allowing the university to island from the grid to keep critical loads operational when the grid goes down.

Clemson University in South Carolina recently added a 2.8 MW steam turbine generator to the 15 MW CHP system already on their campus. The CHP plant, owned and operated by Duke Energy, provides Clemson with steam while also allowing the university to island from the grid to keep critical loads operational when the grid goes down.

Partnerships such as the one between Clemson and Duke Energy allows organizations to leverage external funds to transition to clean energy where they would otherwise be unable to. “Capital cost can be the biggest barrier to installing CHP for critical facilities where a resilient supply of electricity is so important like hospitals, universities, or military bases,” said Christina Kopitopoulou, Senior Project Manager for the NC Clean Energy Technology Center’s Clean Power & Industrial Efficiency Program. Currently, CHP cogeneration systems may qualify for a 10 percent Business Energy Investment Tax Credit for private companies to help offset the investment costs for companies interested in installing CHP.

The U.S. Department of Energy (DOE) Southeast Combined Heat and Power Technical Assistance Partnership (CHP TAP), based at the NC Clean Energy Technology Center at NC State University, promotes and assists in transforming the market for CHP, waste heat to power and district energy technologies/concepts in the following eight southeast states: North Carolina, South Carolina, Tennessee, Kentucky, Georgia, Alabama, Mississippi and Florida, as well as Puerto Rico and the U.S. Virgin Islands. The CHP TAP network provides fact-based, unbiased education and technical assistance to help energy end-users consider the benefits of combined heat and power.

The U.S. Department of Energy (DOE) Southeast Combined Heat and Power Technical Assistance Partnership (CHP TAP), based at the NC Clean Energy Technology Center at NC State University, promotes and assists in transforming the market for CHP, waste heat to power and district energy technologies/concepts in the following eight southeast states: North Carolina, South Carolina, Tennessee, Kentucky, Georgia, Alabama, Mississippi and Florida, as well as Puerto Rico and the U.S. Virgin Islands. The CHP TAP network provides fact-based, unbiased education and technical assistance to help energy end-users consider the benefits of combined heat and power.