Clean Solutions for Clean Energy: Solar Panel Recycling

Within the ever-evolving clean energy industry, there are many considerations when it comes to maintaining processes that are environmentally sustainable. Renewable energy offers a number of benefits including reduced carbon emissions, lower energy costs, and grid resilience. In the renewable energy manufacturing sector, it is important to ensure that all aspects are clean.

Solar Panel Recycling (SPR) is a company that operates according to a circular economy, a model that is designed to reduce waste by reusing, repairing, and recycling materials, with a goal of keeping products in the economy as long as possible. Brett Henderson, CEO and co-founder of SPR, is part of the NC Circular Economy Council, established in 2023 by former North Carolina Department of Environmental Quality Secretary, Elizabeth Biser. The goal of the Council is to increase the quality and quantity of materials that are recovered, expand material recovery capacity, increase support for economic initiatives, strengthen public knowledge about recycling within the state, and to expand partnerships with industries to further the growth of North Carolina’s circular economy.

As a state with over 10 gigawatts of solar PV installed, North Carolina stands to benefit from the growth of companies like SPR in the business of recycling solar panels. The North Carolina Environmental Management Commission recently developed rules for the decommissioning of large-scale renewable energy facilities, including solar generating plants. Starting on November 1, 2025, owners of solar projects larger than 2 megawatts will be required to have decommissioning plans that include consideration of reuse or recycling of solar PV modules.

According to the Carolinas Clean Energy Business Alliance, the creation of these rules for decommissioning and recycling of solar modules had helped support certainty in a key aspect of solar development.

Henderson co-founded SPR in 2023 under the parent company Powerhouse Recycling, an electronics recycler. He recognized that the technology industry was rapidly developing while also becoming more disposable. In 2018 a major utility contacted Powerhouse Recycling looking for an opportunity to recycle around 10,000 panels, which was not a service they offered at the time. After the request, Henderson conducted research and development and traveled overseas to better understand recycling technologies in European and Asian markets.

SPR offers four core services: solar panel recycling, on-site services, transportation, and compliance. Although they offer both residential and commercial services, Henderson said the bulk of solar panel recycling is sought out by commercial and industrial users. These large facilities often have the resources to remove broken panels, load them, and ship them to SPR’s state of the art recycling facilities in North Carolina and Georgia. For utilities or operations and maintenance (O&M) companies that may not have the resources, SPR can provide onsite services ranging from full decommissioning to providing transportation for the material. Often, Henderson says that a utility or energy company hires a contractor that consolidates the panels in one area, then requests a pickup from SPR, who will then load the trucks and transport them to the recycling facilities. When transporting material, they ensure that the minimum amount of trucks are used to reduce their carbon footprint. Additionally, they plan to establish recycling centers across the United States to decrease the distance the material has to travel. SPR has an in-house compliance team that assures projects are compliant with Department of Transportation (DOT) regulations, as well as state and federal regulations. 31 states currently have decommissioning recycling policies, but they are rapidly changing.

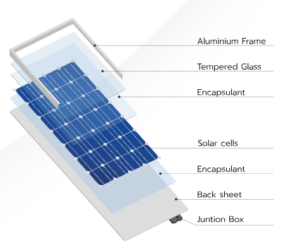

One of the largest challenges in solar panel recycling that SPR puts effort into is cleanly separating the commodities. Henderson emphasizes that because there are layers to solar panels that are all encapsulated, there isn’t a simple way to separate the components. Without separating the commodities, there is little to be recycled. Using proprietary technologies, SPR is able to separate them, resulting in the extraction of clean glass, silicone power, silver, copper, plastics, and aluminum that will go into supply chains. The silicone typically goes back to the technology industry, used for semiconductors and batteries. The plastics are often used for shoe soles and sandals. Henderson says the goal is to reuse the glass in solar panel manufacturing, but that has not yet been solved. He is confident that SPR will be able to do this within a couple of years as they have been working with glass manufacturers to address this. Although the glass can’t be reused for solar panels, it can be used in concrete cement manufacturing, and it boasts large carbon dioxide savings. The aluminum is able to go back into creating solar panels, making it “fully circular”.

Henderson explains there are three technologies that offer efficient commodity separation mechanical, metallurgical, and thermal. He says, “Right now, we are using mechanical because it doesn’t produce any chemical waste.” The process also has a low power consumption and doesn’t use heat which would otherwise result in air emissions. They also utilize filtration systems and dust collections systems to contain the processes.

Another challenge SPR is working to combat is the viability of residential solar panel recycling, due to the high cost of dispatching a truck for a small amount of panels. SPR has collaborated with one of the largest associations for solar and clean energy, the Solar Energy Industries Association (SEIA), to develop a pilot program that is the first of its kind that will allow residents to drop off solar panels to recycle. SPR will wait for the panels to accumulate, then dispatch a truck to transport them to a recycling center, thus increasing efficiency. The program will launch on January 1, 2025, in Mecklenburg County, NC.

Some may wonder why solar panels removed from utility scale generation facilities that can still produce power aren’t being re-used for secondary markets, and Henderson has an answer for this. “Tracked like any commodity or market, you can get a new warrantied panel for a lower watt price.” He also says that secondary markets are driven off by the low price of new panels. Solar panels are fragile to ship as well, making the export of panels very limited.

Henderson notes that there has been a “promising shift in the last 12 months, especially with the larger energy companies”, as those companies need to be clean throughout the entire process of clean energy deployment. SPR’s main mission is to educate the public and show that there is clean and efficient recycling available. Henderson encourages everyone to seek out the recycling process, to ensure that no component of a solar panel reaches the landfill. “In a clean energy industry, we can’t advocate for clean energy while choosing to landfill and not properly recycle solar panels.” Many landfills in North Carolina only have a 10-year capacity remaining, and solar panels are a “brand new waste stream that hasn’t been accounted for.” The good news is that this industry seems to have bipartisan support and can contribute to the advancement of clean recycling processes, leading to a circular economy.