Southeast DOE TAP Hosts a Webinar about Decarbonization through Onsite Energy

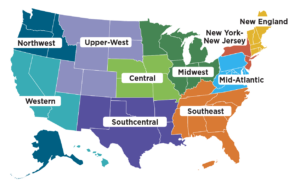

The North Carolina Clean Energy Technology Center (NCCETC) manages the Southeast Onsite Energy Technical Assistance Partnership (TAP) which is funded by the United States Department of Energy (U.S. DOE) under the Industrial Efficiency and Decarbonization Office Onsite Energy Program. There are ten Onsite Energy TAPs nationwide covering each region in the United States, with a goal to assist industrial facilities and large energy users in reducing emissions, transitioning to clean energy, lowering costs, and overall contributing to a clean energy economy.

Along with technical assistance, the TAPs also prioritize end-user engagement and stakeholder engagement, by engaging through conferences, workshops, and partnering to support their clean energy development.

The Southeast Onsite Energy TAP offers technical assistance from a team of professionals with experience in onsite energy consisting of engineers, scientists and policy analysts. This TAP serves Alabama, Florida, Georgia, Kentucky, Mississippi, North Carolina, Puerto Rico, South Carolina, Tennessee, and the Virgin Islands. The team, led by Isaac Panzarella, Director, and Art Samberg, Assistant Director, are holding a three-part webinar series open to the public to share the benefits of onsite energy, discuss policies, programs, and funding, and provide examples of facilities and end users that have deployed onsite energy.

On July 11, 2024, the team hosted the first webinar of the series, Decarbonization Begins Onsite, which focused on onsite energy benefits and awareness of technology applications for onsite energy in manufacturing and on campuses.

The webinar began with an introduction to the Onsite Energy TAPs and the Southeast Onsite Energy TAP team, followed by guidance on applying technologies for onsite energy. Isaac Panzarella shared the broad range of technologies that are suitable to maintain large energy loads which include battery storage, combined heat and power, district energy, geothermal, industrial heat pumps, renewable fuels, solar PV, solar thermal, thermal storage, and wind. He described Onsite Energy as a “key sustainability strategy” and gave examples of projects where the technologies have been implemented.

In Greenville, South Carolina, a BMW manufacturing facility implemented a 13-megawatt combined heat and power (CHP) fueled by landfill gas (LFG) as their primary technology. As processes that require thermal energy can be energy and emissions intensive, CHP is a viable alternative that produces electricity as well as thermal energy more efficiently. Panzarella shared that landfill gas is a great solution for long term sustainability, and the BMW facility sees an annual greenhouse emissions reduction of 92,000 metric tons of carbon dioxide (MTCO2e) from the landfill gas CHP system.

NC State University is home to many students and hosts critical research projects, making onsite energy technologies a key strategy for low emission resilient energy. Both the Main campus and Centennial campus have their own CHP systems and microgrids, which supply essential power and thermal energy to their respective campuses. An annual greenhouse gas emission reduction of over 50,000 MTCO2e is seen from the 17 megawatts of CHP alone at NC State. The University has a combination of other onsite energy systems including a solar PV array on the roof of Fitts Woolard Hall, a battery energy storage system, and a chilled water storage tank that holds 3.3 million gallons.

One of the more recent onsite energy projects in the Southeast was completed in 2023 by United Therapeutics, at their pharmaceutical manufacturing facility in Morrisville, North Carolina. They set a goal to develop a net zero facility early on in the process, with an objective of avoiding the use of fossil fuels onsite. With a need for extensive cold storage facilities to secure perishable medicine, there was a requirement for resilient energy. The facility incorporates a 434-kilowatt rooftop solar PV array, a 6.2 megawatt-hour battery storage, and a geothermal heating and cooling system. With a geothermal system consisting of 40 closed loop wells and a depth of 500 feet, along with maximized solar PV on their rooftop, their early planning allowed for an integrated design that kept costs lower from the start. United Therapeutics was able to achieve their net zero goal and overall uses 31% less energy than the baseline. This energy performance was a key contribution to the facility’s achievement of becoming LEED Certified Gold shortly after opening.

Panzarella then shared the process of site screening for onsite energy with the attendees and defined it in the context of a three-step pathway to decarbonization. The first step is to avoid or use less energy as a whole, the second is to pivot to low carbon solutions like electrification or onsite renewable energy, followed by the final step, to sequester unabated emissions through carbon capture and storage. Deploying onsite energy technology is an important solution in step two of the process, which can begin with a portfolio analysis for organizations with multiple sites. The portfolio analysis ranges from regional geographic factors to site-specific factors, with the TAPs looking at sufficient solar or wind resources, renewable portfolio standards, long-term outlook for the facility, available land, and many more considerations.

A screening of site-level technology can then be conducted to evaluate the viability of each technology based on site conditions including electricity rate, demand charges, natural gas prices, available roof and land space, high heating loads, and 24/7 electricity and heating loads. Then, the TAPs will recommend which individual technologies will be the most beneficial for the site, and also how a combination of technologies will perform.

The National Renewable Energy Laboratory REopt Tool for Evaluating Onsite Energy is used to evaluate the feasibility of each technology, as it optimizes a range of technologies based on the data inputs and provides integrated cost-optimal solutions. The tool provides financial and resiliency modes to ensure a well-rounded evaluation for facilities. REopt is free to use, and as part of the technical assistance provided, the NCCETC team inputs distributed energy resources, site attributes, and goals that are identified at the beginning of the process. REopt then models decisions and constraints, and gives results of distributed energy resource sizes, project economics, and progress toward goals. The TAP uses this information to advise facilities and organizations on the best technologies to implement and then offers guidance on incentives, programs, and policies that are applicable to the specific project.

Assistant Director of the Southeast Onsite Energy TAP, Art Samberg, led the portion of the webinar on the benefits of onsite energy; energy cost, emissions reduction, and resilience. Samberg identified the two frameworks for reporting greenhouse gas emissions tied to a site’s utility electricity consumption. An inventory, or attributional, accounting framework estimates a site’s indirect emissions from grid electricity consumption, which is based on average grid emissions. A project, or consequential, accounting framework is a preferred method for estimating the emissions impacts of grid connected onsite energy projects, and accounts for the changes in direct emissions on the grid as a consequence of onsite energy generation. The project framework is based on marginal grid emissions factors that can be estimated using EPA tools AVERT and eGRID.

For some facilities, energy resilience capabilities can be the most important driver for onsite energy. At manufacturing facilities where a short power outage can cost hours of production and hundreds of thousands of dollars, onsite energy can mitigate these impacts by reducing dependence on the utility grid. Samberg said, “energy resilience has always been an important part of the onsite energy picture” and emphasized that it allows facilities to operate with flexibility and lower costs.

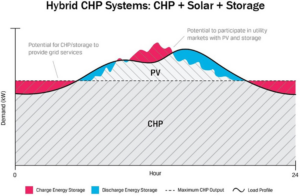

Combined heat and power as a strategy for decarbonization was also touched on, as it can be used for a wide range of applications and has the ability to combine solar PV, battery storage, wind, and other technologies. “What’s interesting about CHP is the high annual low-capacity factor, and the fact that you’re using the same fuel for the thermal and electric energy at your site,” said Samberg. Renewable natural gas is also a high resource potential, due to its displacement of fossil fuels, contributions to sustainable waste management, and low costs.

Lastly, Panzarella reminded the attendees how to work with their regional Onsite Energy TAP. The first thing a facility or organization should do is contact the Onsite Energy TAP in their region to begin looking at opportunities. Then, the TAP will meet with the user to discuss interest in onsite energy and learn about the facility’s needs. Site data will then be collected, and the TAP will conduct an analysis to screen different technologies. Initially, the analysis does not require a site visit, but in an advanced analysis there may be a need to visit the site to strategize where to install equipment among other reasons. When the results are complete, the TAP will review and discuss next steps with the user. Panzarella stated the timeline is typically less than thirty days from the initial contact to the discussion of results, but it depends on the amount of data and energy costs that need to be reviewed. The TAPs don’t advocate for a particular vendor for technology implementation following the discussion of results, but the team can assist the user in identifying the range of vendors available and the services they provide. As part of the technical assistance, the team can also provide a third-party unbiased review of specifications and proposals that an installer provides for a site.

The U.S. DOE Office of Manufacturing and Energy Supply Chains offers an Industrial Research and Assessment Center Implementation Grant Program aimed to assist small and medium-sized manufacturers (SMMs) with implementing recommendations made by Onsite Energy TAPs. There is $80 million in funding available under the program, with grant awards of up to $300,000 per manufacturer per quarter with a 50% cost share requirement. To be eligible, a facility’s annual gross sales must be fewer than $100 million, consist of fewer than 500 employees, and have annual energy bills ranging between $100,000 and $3.5 million. The Onsite Energy TAPs are available to meet with users applying for the grant to answer questions and provide a technical review, but the team cannot fill out the application for a site. For more information visit: https://www.energywerx.org/opportunities/iacimplementationgrants

Technical assistance provided by the Onsite Energy TAPs is offered at no cost due to U.S. DOE funding. To inquire about the services the Southeast Onsite Energy TAP provides or to request technical assistance, contact Isaac Panzarella at ipanzarella@ncsu.edu or Art Samberg at asamber@ncsu.edu.

The Southeast Onsite Energy TAP will be hosting two more webinars this summer! Tune in at 2:00pm EST on August 8, 2024, to learn about policies, programs, and funding, and on September 5, 2024, to hear about best practices for deploying onsite energy. Sign up for the webinars today!